We take liberty in introducing ' PR Services ' as a team of technocrats engaged in the service of edible oil /cooking oil industries. We are dedicated to engineer the following:

• Process equipments for complete refining plant with all perpherals requirement for refining process

• Turnkey Edible oil processing units equipped with latest technology and trends in refining of any seed and fruit oil.

• Our execution starts right from concept to commissioning as per conformance to the best in the market world wide

• Solutions for backward and forward integration.

• We are based in Chandigarh, the city beautiful and planned city in affluent northern India.

Project turn key basis

- Edible oil / cooking oil

- Complete refining project with latest technologies and development for all vegetable oils consisting of

- Degumming , neutralisation , washing and drying

- Bleaching process

- Dewaxing / winte rization

- Deacidification / deodorization

- Lecithin / margarine / esterification / bakery shortening and hydrogenation

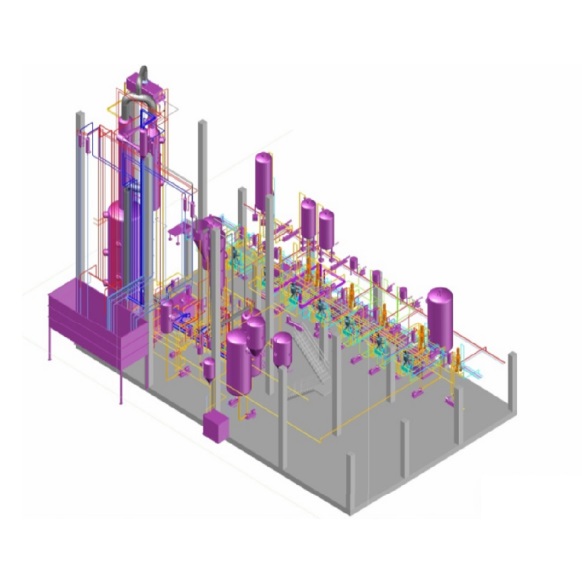

Complete Refinery

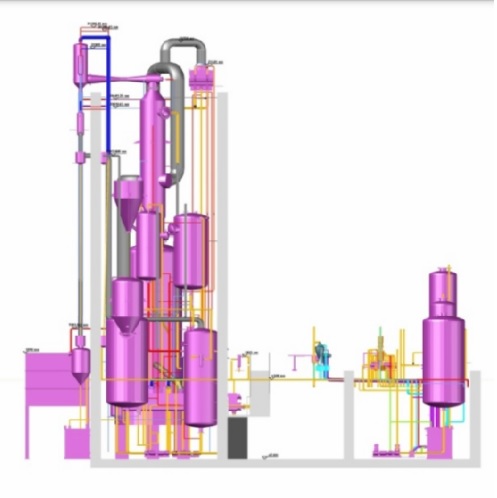

Complete Refinery System

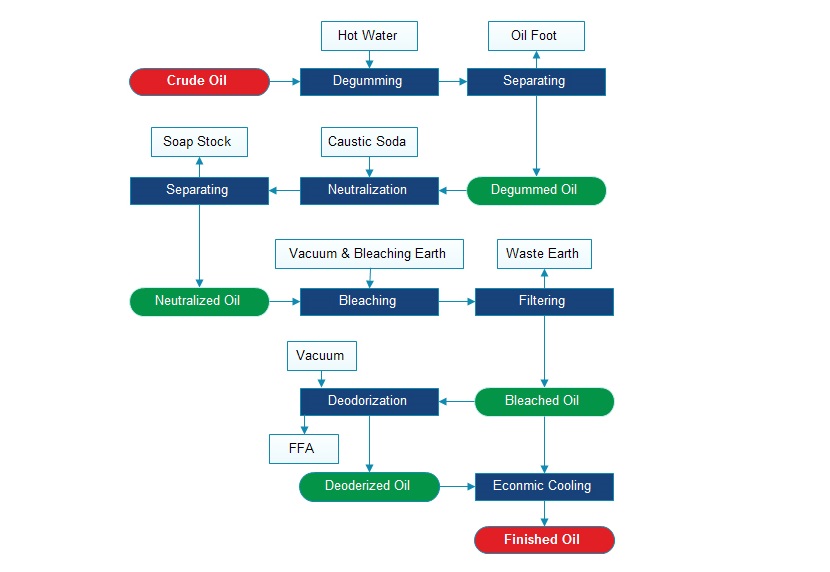

Basic steps for oil Refining

Step 1 Degumming , Neutralisation washing and drying

The purpose of Degumming vegetable cds is to remove Gums . All oils have hydratable & non - hydratable gums . Hydratable gums are removed by treating oils with water , known as water Degumming . Non - hydratable gums are removed by treating oils with acids , known as Acid Degumming .

The purpose of Neutralizing Vegetable oils is to remove Free Fatty Acids ( FFAs ) , FFAs are treated with caustic soda ( NaOH ) .

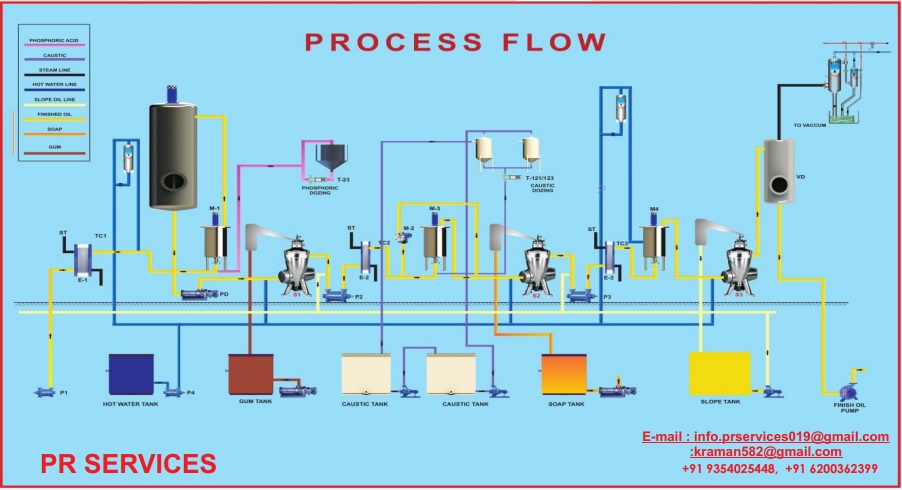

Degumming / Neutralisation , Washing , Drying---- Sketch

Degumming / Neutralisation , Washing , Drying

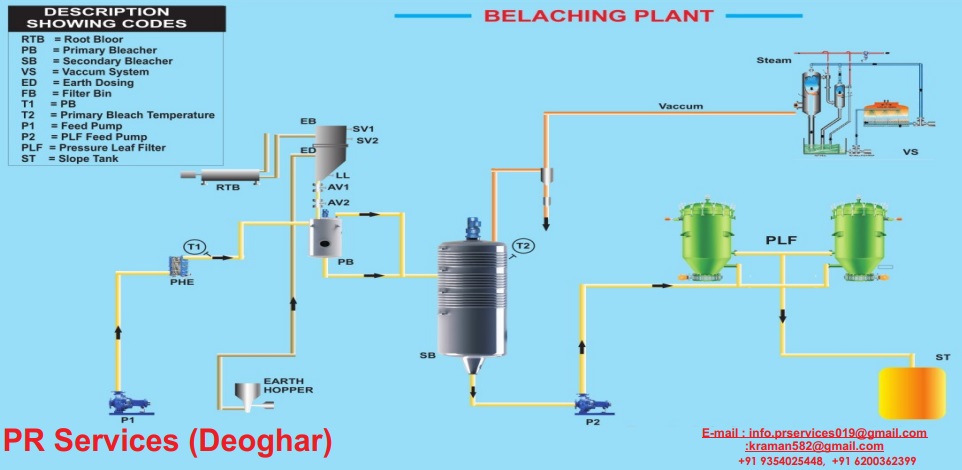

The purpose of bleaching is to remove color pigments contained in vegetable oils . The oil is treated with Bleaching Clays that adsorb the color pigments . The clay is filtered and the clean bleached oil is stored for further processine

Bleaching/Filtration

Filteration through Pressure leaf filters

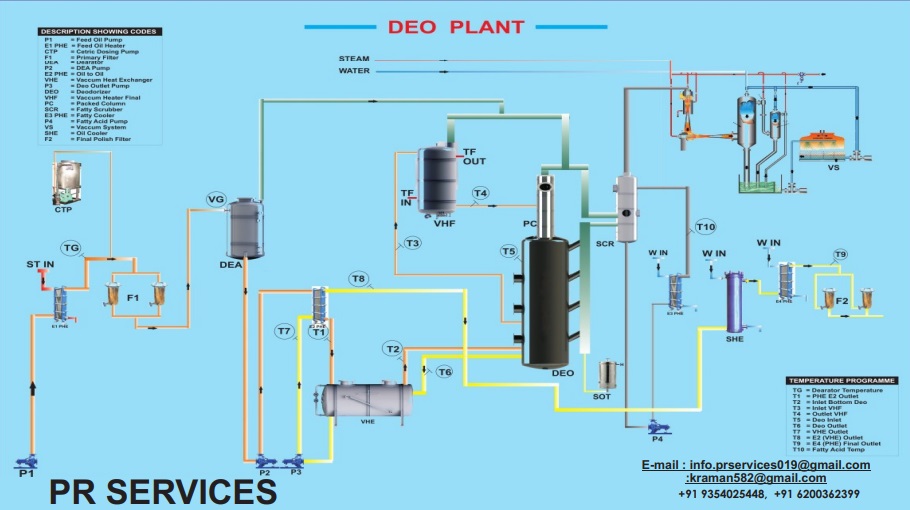

The purpose of Deodorizing Vegetable oils is to remove odor substances . The oil is subjected to steam distillation under high temperature and vacuum to evaporate all odor substances . The resulting deodorized oil is almost bland and tasteless .

Deacidification/ Deodorisation

Iran Refinery Shortmix Bleach Deo

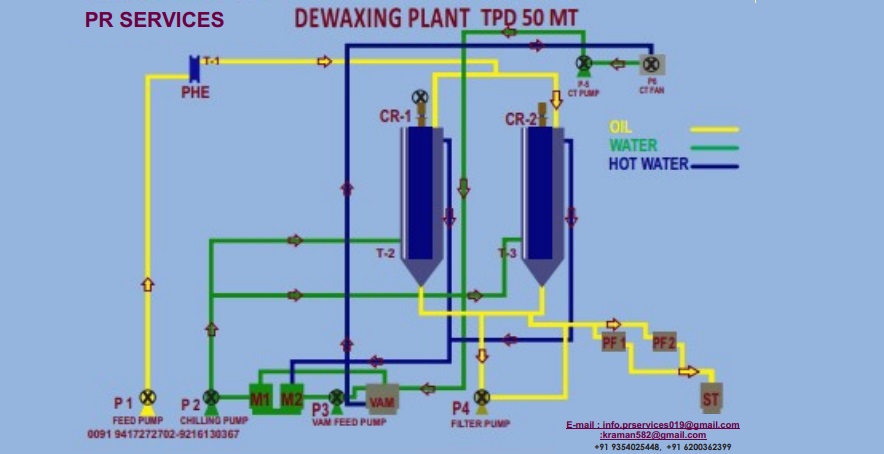

The purpose of Winterization Vegetable oils is to remove waxes especially in those oils that contain waxes . Such oils are subjected to chilling and filtration to remove waxes and other high melting point substances .

Dewaxing

Winterization sunflower/cotton seed

Palm Oil Fractionation Plant

Consultancy / guidance / outsourcing

We have capabilities and complete acquaintances with best technologies following allied plants related to veg . oil

1. Oil mill / expeller units for the yield of oil from all veg . oil seeds and oil bearing fruits .

2. Solvent extraction and preparatory sections for all veg , oil cakes .

3. Fat splitting and distillation

4. Soap and detergent plants